Daily cleaning of CNC gear hobbing machine

2020-11-16

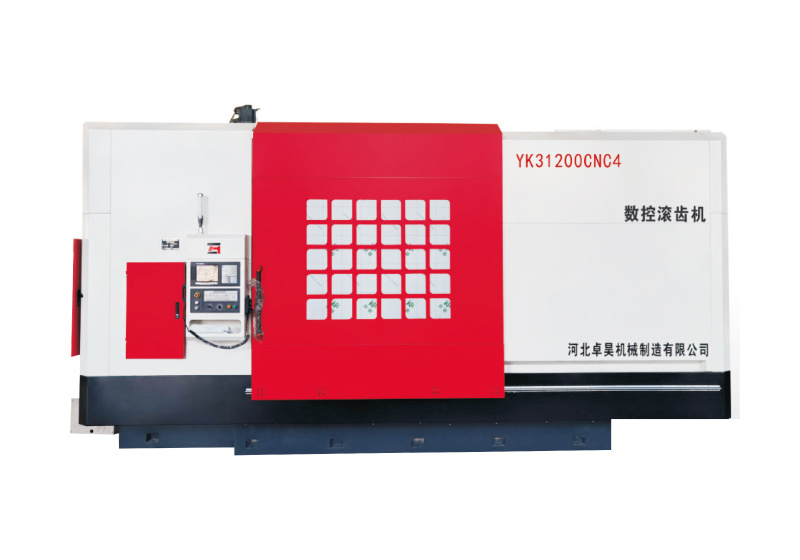

CNC gear hobbing machine is a widely used machine tool among gear processing machines. It can cut spur and helical spur gears, as well as worm gears and sprockets. A gear processing machine that processes straight, helical and herringbone cylindrical gears and worm gears with hobs according to the processing method. When using special hobs, the machine tool can also process various special tooth-shaped workpieces, such as splines and sprockets. The processing accuracy of ordinary gear hobbing machines is 7 to 6, and the processing accuracy of high-precision gear hobbing machines is 4 to 3. The maximum processing diameter is 15 meters. The CNC gear hobbing machine has a reasonable structure, compact layout, and easy operation and maintenance. It can process one or more times according to the size and accuracy of the workpiece. At the end of cutting, the machine tool can actively park the turret slide and move it quickly. In order to improve the accuracy of CNC gear hobbing machine, we must do daily cleaning work:

1. Clean the outside of the control system and keep it clean. Do not use items containing chemical components to clean the billing button.

2. Clean the chips on the fixed table and maintain it carefully to avoid damage.

3. Clean the machine tool with a clean cloth. The surface of the machine tool is clean and free of oil and dust.

4. Clean the chips on the chip filter device and check whether the cutting fluid requirements are met.

The next one:

Contact Us

Service Phone:

+86-13630891203, +86-13930960916

E-mail:

554590975@qq.com

Address:

No.16, Xingwan Industrial Zone, Ren County, Xingtai City, Hebei Province