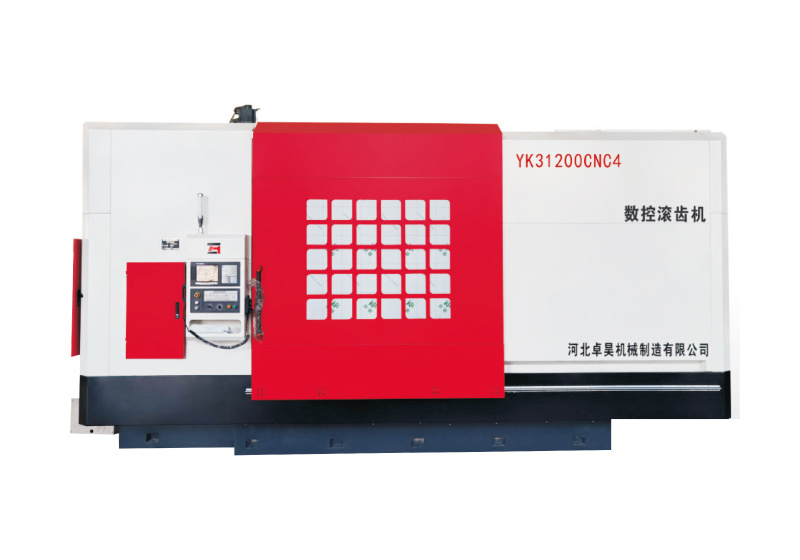

Safety operating procedures for high-speed gear hobbing machines

2020-12-01

feature:

1. Suitable for batch, small batch and single-piece production of cylindrical helical gears and worm gears. It can also perform roll cutting on Huajian shafts with a certain parameter range;

2. Easy to adjust and equipped with automatic parking mechanism;

3. Gear processing machine tools widely use reliable safety devices and high-speed gear hobbing machines. Gear hobbing machines can cut straight and helical gears, as well as worm gears and sprockets. A gear processing machine that processes straight, helical and herringbone cylindrical gears and worm gears with hobs according to the processing method. When using special hobs, the machine tool can also process various special tooth-shaped workpieces, such as splines and sprockets.

Safety operating procedures:

1. When milling gears, the height between the bottom surface of the blank and the workbench cannot be lower than the height specified by the machine tool;

2. The diameter of the blank washer should be less than 3 mm the diameter of the root circle of the gear to be processed;

3. The tool holder, tool holder holder, tool holder gasket and knife hole should be wiped clean. When installing the comb milling cutter, insert the corresponding key;

4. When moving the angle of the tool holder, pay attention to the sliding of the tool holder.

5. According to the requirements of the gear to be processed, check the adjusting parts before cutting;

6. When milling helical gears, be sure to clamp the workpiece firmly to prevent it from rotating during milling. Do not collide with the tool holder, do not disassemble the lead screw, and the tool must be retracted when lifting the tool holder;

7. When opening quickly, the milling cutter is not allowed to collide with the workpiece, and the distance when exiting should not be too long to avoid collision between the tool holder and the workbench.

8. The module and diameter of the gear to be processed must not exceed the technical specifications of the machine tool;

9. When replacing wheels, please cut off the power supply.

The next one:

Contact Us

Service Phone:

+86-13630891203, +86-13930960916

E-mail:

554590975@qq.com

Address:

No.16, Xingwan Industrial Zone, Ren County, Xingtai City, Hebei Province