Explain the areas in which gear hobbing machines can be used

2020-12-16

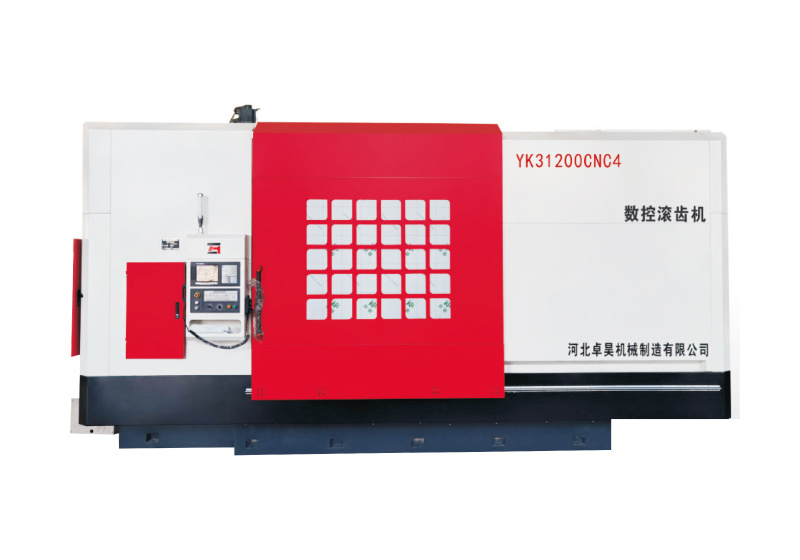

A gear hobbing machine is a gear processing machine that uses hobs to process spur gears, helical gears, and herringbone cylindrical gears and worm gears based on the generation method. A gear processing machine that processes straight, bevel, and herringbone cylindrical gears and worm gears with hobs according to a processing method. When using special hobs, the machine can also process a variety of special toothed workpieces, such as splines and sprockets. Generally, the machining accuracy of gear hobbing machines is level 7 to level 6, and the processing accuracy of high-precision gear hobbing machines is level 4 to level 3. The processing diameter is 15 meters.

Gear hobbing machines are divided into vertical and horizontal types according to their layout. Most large and medium-sized gear hobbing machines are vertical, while small hobbing machines and gear hobbing machines dedicated to processing long-axis gears are horizontal. Vertical gear hobbing machines are divided into two types: table movement and column movement. When the vertical hobbing machine is running, the hob is installed on the hob spindle and driven to rotate by the main motor. The tool holder can be moved straight along the vertical columns and angled around the horizontal axis. The workpiece is installed on the workbench and rotates driven by the indexing worm gear pair, and generates motion with the movement of the hob. When tapping helical gears, the differential mechanism causes the workpiece to roll accordingly. The table (or column) can be moved along the bed for guided rolling to accommodate different workpiece diameters and for radial feed. The tool holder of some gear hobbing machines can also move along the axis of the hob to machine the worm gear with tangential feed. The large gear hobbing machine is also equipped with a single-tooth indexing mechanism, a finger milling cutter holder and a differential reversible mechanism for processing herringbone gears.

Gear hobbing machines are widely used in various machinery manufacturing industries, such as automobiles, tractors, machine tools, construction machinery, mining machinery, metallurgical machinery, petroleum, aircraft and spacecraft. Gear processing machine tools can process various cylindrical gears, bevel gears and other tooth-shaped parts. The types of gear processing machine tools are complex and include small machine tools for processing gears with a diameter of a few millimeters, large machine tools for processing gears with a diameter of more than ten meters, and a large number of high-efficiency machine tools.

Previous:

Contact Us

Service Phone:

+86-13630891203, +86-13930960916

E-mail:

554590975@qq.com

Address:

No.16, Xingwan Industrial Zone, Ren County, Xingtai City, Hebei Province