Overview of gear hobbing machine

2020-06-04

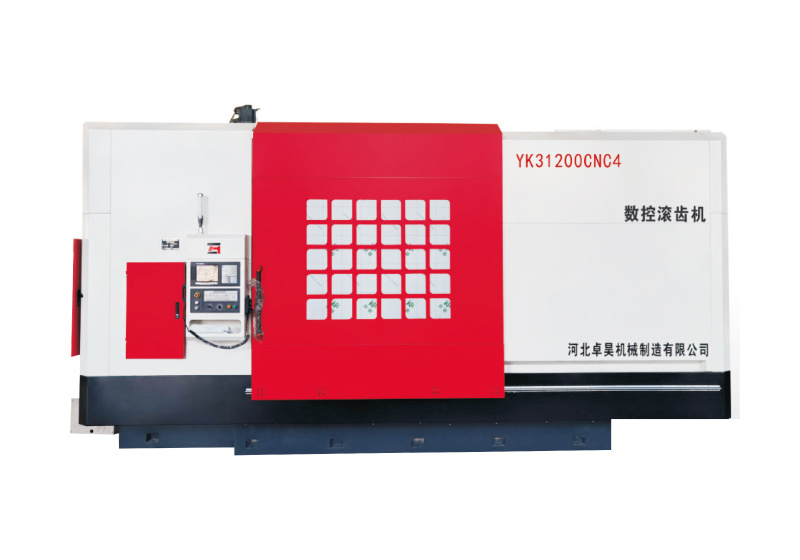

Gear hobbing machine is one of the most widely used gear processing machines. It can cut spur gears, helical gears, worm gears, sprockets, etc. A gear processing machine that uses a hob to process spur, helical, and herringbone cylindrical gears and worm gears through the generation method. When using special hobs, the machine tool can also process various special tooth-shaped workpieces, such as splines and sprockets.

Features of gear hobbing machine:

(1) Small batches and single-piece production of cylindrical helical gears and worm gears can also be hobbing spline shafts within a certain parameter range.

(2) Easy to adjust and equipped with automatic parking mechanism

(3) Gear hobbing machines with reliable safety devices and automatic lubrication are widely used machine tools in gear processing. Straight and helical gears can be cut on a hobbing machine, as can worm gears and sprockets.

Classification of gear hobbing machines:

Gear hobbing machines can be divided into vertical and horizontal structures according to their layout. Large and medium-sized hobbing machines are mostly vertical, while small hobbing machines are used. Vertical hobbing machines and long-size shafts dedicated to hobbing machines are all handled horizontally. Vertical gear hobbing machines are divided into two types of motion and travel columns. When the hob is working vertically, the hob is mounted on the main shaft of the hob and is driven by a motor driven by the main rotary motion. The tool holder can move vertically along the guide column, and it can also be adjusted in angle around the horizontal axis. The workpiece is installed on the workbench, and the worm gear is composed of components that move together to produce motion driven by the indexing rotation of the hob. When helical gear hobbing, it is used to correspond to the differential mechanism on the additional rotating workpiece. The table (or column) can be rolled up and moved along the bed guide to accommodate the radial feed of different workpiece diameters. Some hobbing tool heads can also move axially on the hob, allowing the feed worm to be handled in a restricted manner. There is also a large hobbing machine single tooth indexing mechanism, finger cutter cage and differential processing herringbone gear reversing mechanism or similar.

Previous:

Contact Us

Service Phone:

+86-13630891203, +86-13930960916

E-mail:

554590975@qq.com

Address:

No.16, Xingwan Industrial Zone, Ren County, Xingtai City, Hebei Province