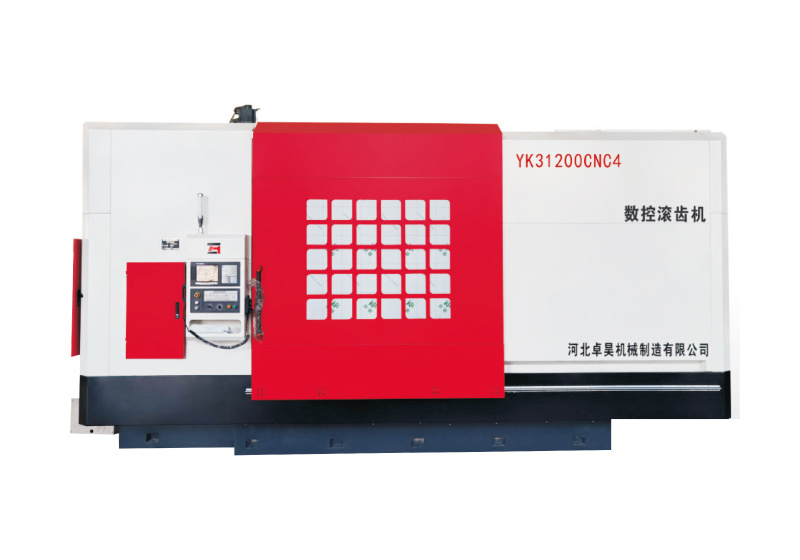

Application of CNC gear hobbing machine

2020-06-05

With the rapid development of social economy and the continuous progress of modern society, the level of mechanization in all walks of life in society has been continuously improved. The improvement of mechanization level has improved social productivity and promoted the rapid development of society. As an important basic component in industrial production, gears play an important role in industrial production. At present, the gear industry has developed into a large-scale industry of basic mechanical parts in China. CNC gear hobbing machines are widely used in automobiles, tractors, machine tools, engineering machinery, mining machinery, metallurgical machinery, petroleum, instrumentation, aircraft and spacecraft and other machinery. Gear processing machine tools can process various cylindrical gears, bevel gears and other toothed parts. Gear processing machine tools come in a wide variety of specifications, including small machines for processing gears with a diameter of a few millimeters, large machines for processing gears with a diameter of more than ten meters, and high-precision machines for precision gears. Equipped with efficient machine tools for mass production.

As industrial production puts forward higher requirements for the accuracy and quality of gears, it also puts forward higher requirements for the processing accuracy of CNC gear hobbing machines. This accordingly led to the development of CNC gear hobbing machines for gear production machinery. Therefore, our country has incorporated the research and development of CNC gear hobbing machines into the scientific system and achieved remarkable results. The level of manufacturing has been greatly improved. At present, it can independently produce CNC gear hobbing machines, and its performance has been greatly improved to better meet user requirements.

At present, this CNC gear hobbing machine is suitable for batch, small batch and single-piece production and processing of cylindrical gears and worm gears. Drum gears with certain parameters can also be used for continuous cutting of spline hobs with a length of 6 teeth. Spline shaft less than 300 and less than 6 teeth. Sprockets can be cut with a sprocket hob. When machining cylindrical gears, reverse milling and down milling hobbing can be used, and the entire tooth width can be machined by axial feed (vertical feed). The CNC hobbing machine adopts radial feed method for hobbing ordinary worm gears.

Previous:

The next one:

Contact Us

Service Phone:

+86-13630891203, +86-13930960916

E-mail:

554590975@qq.com

Address:

No.16, Xingwan Industrial Zone, Ren County, Xingtai City, Hebei Province