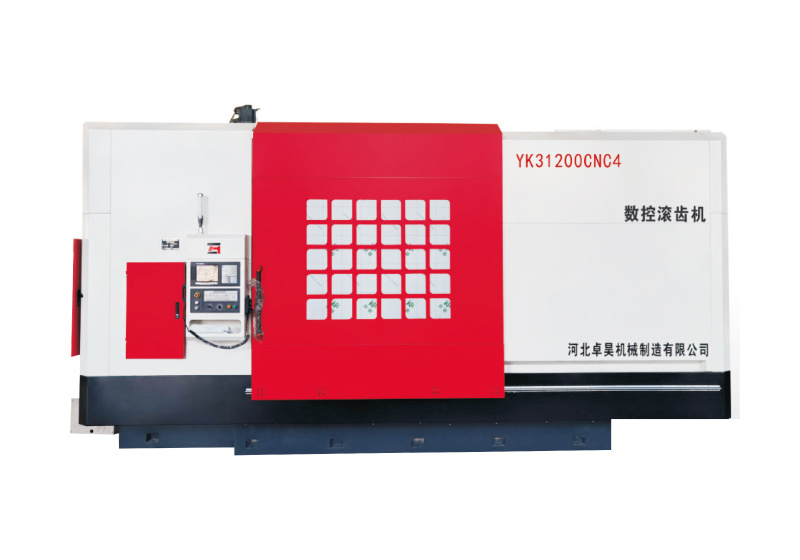

Small gear hobbing machine

2020-09-02

The main purpose and characteristics of the small gear hobbing machine are that the machine tool is mainly used to process large gears with a diameter less than φ80mm and spur gears and turbines with a diameter of 1.5mm. Different levels of processing accuracy can be provided according to user needs. Helical gears with helix angles within ±18° can also be processed. The advantages of this machine tool are simple operation and adjustment, reliable performance and high processing accuracy. This machine is a semi-automatic gear hobbing machine. After the workpiece is mounted and the machine is started, the feed cam will transport the tool holder to the cutting position. After the cutting is completed, the hob will automatically leave contact with the workpiece. This feature facilitates multi-machine management. It is particularly suitable for handling gears in instrumentation, light industry and electronic equipment.

Functions of small gear hobbing machine:

1. The operator only needs to press a button and the machine will run automatically. The loading and unloading of workpieces is simple and convenient. Operators can use multiple machines simultaneously, which is very efficient.

2. The main motor is installed behind the stove, so no transmission force is transmitted to the stove, and the motor itself is designed like a flywheel, so the speed of the stove is stable.

3. The hob shaft bracket is made by high-precision special precision processing.

4. The hob holder has a large movable area, which can reduce the wear of the cutter head. The 15-degree tilt of the stand eliminates operator pressure.

5. The longitudinally designed hob shaft discharges cutting powder smoothly, and the hob shaft is located on the opposite side of the working surface, so the workpiece is easily accessible.

6. All gears used inside the machine are heat treated and undergo advanced grinding.

7. Both the vertical and horizontal axes are controlled by NC. The program is simple, the longitudinal cutting size is accurate, and the processing is stable, especially the gear shaft processing.

8. According to the self-developed two-axis control processing software program, drum-shaped teeth and spiral teeth can be processed. In recent years, in order to prevent gear noise and vibration, it is increasingly necessary to treat drum teeth, especially for dish gears.

9. The main motor controlled by the frequency converter can change the speed of the hob shaft at will, so the best processing conditions can be selected.

10. Due to the use of longitudinal sliding rods and horizontal sliding rods, no machine maintenance is required.

The next one:

Contact Us

Service Phone:

+86-13630891203, +86-13930960916

E-mail:

554590975@qq.com

Address:

No.16, Xingwan Industrial Zone, Ren County, Xingtai City, Hebei Province