What are the characteristics of gear hobbing machines?

2020-09-14

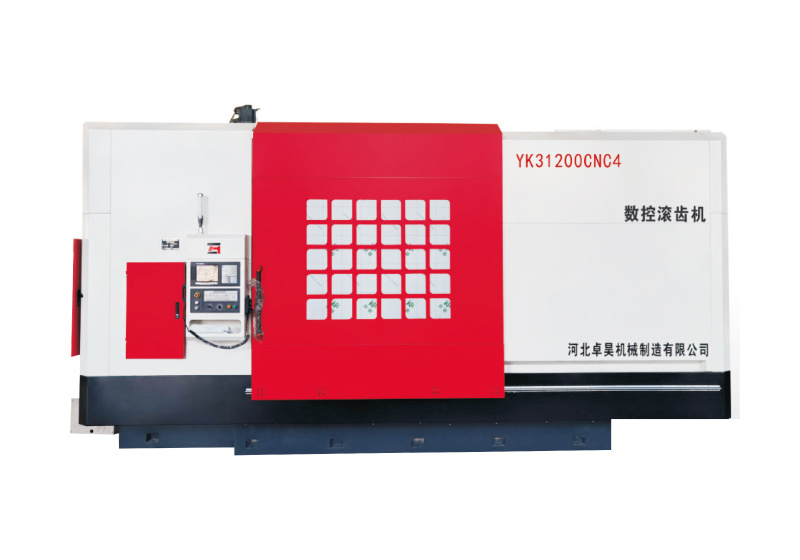

Gear hobbing machines are the most widely used machine tools among gear processing machines. It can cut straight cylindrical and helical cylindrical gears, as well as worm gears, sprockets, etc. on gear hobbing machines. The machine can also machine splines when using special hobs. And special tooth-shaped workpieces such as sprockets.

It is widely used in various machinery manufacturing industries, such as automobiles, tractors, machine tools, engineering machinery, mining machinery, metallurgical machinery, petroleum, instruments, aircraft and spacecraft.

Gear processing machine tools come in a wide variety of specifications, including small machine tools for processing gears with a diameter of a few millimeters, large machine tools for processing gears with a diameter of more than ten meters, and high-precision machine tools for processing precision gears. For mass production.

The following is a brief introduction to the characteristics of gear hobbing machines:

1. The processing principle of the hobbing machine is based on the forming principle of gears. Factors such as the followability and rapidity of the hobbing mechanical feed system and the cost of modification are taken into consideration, while the original ordinary gear hobbing machine is retained. On the basis of the transmission chain, according to the two-coordinate arc interpolation principle in CNC theory, the vertical feed motion and horizontal radial feed of the machine tool are corrected through CNC to achieve gear processing.

2. Analysis of gear hobbing machine transmission chain The gear hobbing machine should have the following transmission chains: main transmission chain, power generation transmission chain, vertical feed transmission chain, axial feed transmission chain, and radial feed transmission chain.

3. Working movement of gear hobbing machine

(1) Main movement: The main movement is the rotational movement of the hob.

(2) Generate motion: The rotation of the furnace frame and workpiece is driven by a servo motor to drive the rotation of the furnace frame and workpiece. The servo motor moves according to the control instructions to strictly ensure the synchronization between the hob and the workpiece.

4. The CNC system of the gear hobbing machine uses an open motion control card to drive each axis motor, giving full play to the advantages of software and hardware on the CNC platform and enriching the development environment. The hardware circuit consists of peripheral devices, signal conversion circuits and auxiliary circuits, forming a complete and simple CNC system to complete a series of functions, such as program input and processing, display and motor driving.

The next one:

Contact Us

Service Phone:

+86-13630891203, +86-13930960916

E-mail:

554590975@qq.com

Address:

No.16, Xingwan Industrial Zone, Ren County, Xingtai City, Hebei Province