What categories are gear hobbing machines divided into?

2020-09-22

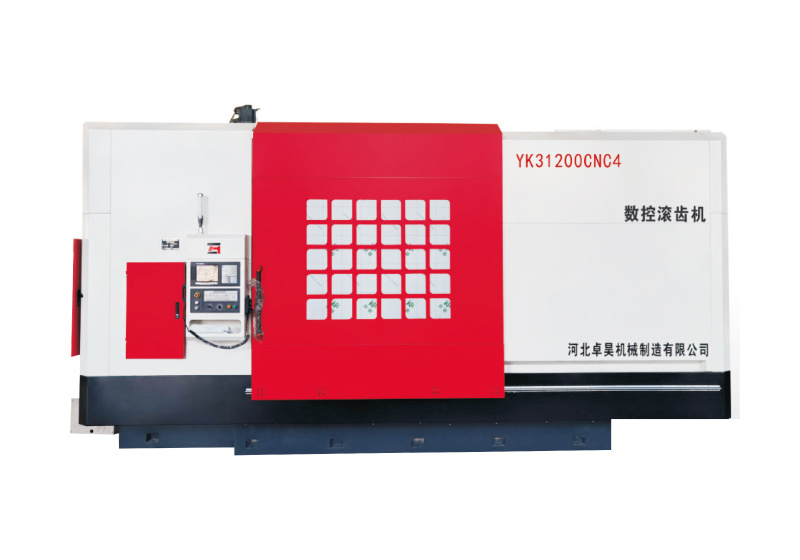

Gear hobbing machines are divided into vertical and horizontal types according to their layout. Most of the large and medium-sized hobbing machines are vertical, while small hobbing machines, vertical hobbing machines and hobbing machines dedicated to processing long-axis gears are all horizontal. Vertical gear hobbing machines are divided into two types: table movement and column movement. When the vertical gear hobbing machine is working, the hob is installed on the hob spindle and is driven by the main motor to perform rotational motion. The tool holder can be moved vertically along the column guide rails, or the angle can be adjusted around the horizontal axis. The workpiece is installed on the workbench and rotates driven by the indexing worm gear pair, and generates motion with the movement of the hob. When tapping into the helical gear, the differential mechanism will cause corresponding additional rotation of the workpiece. The table (or column) can be moved along the bed by guided rolling to accommodate different workpiece diameters and provide radial feed. The tool holder of some gear hobbing machines can also move along the axis of the hob to machine the worm gear with tangential feed. The large gear hobbing machine is also equipped with a single-tooth indexing mechanism, which refers to the milling cutter holder and a differential reversing mechanism for processing herringbone gears.

The next one:

Contact Us

Service Phone:

+86-13630891203, +86-13930960916

E-mail:

554590975@qq.com

Address:

No.16, Xingwan Industrial Zone, Ren County, Xingtai City, Hebei Province