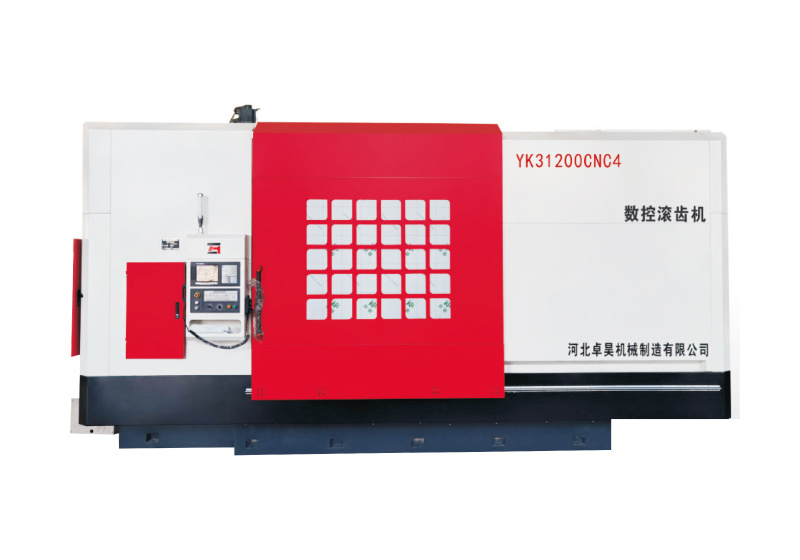

Analysis of the key factors of gear hobbing machine casting and processing

2021-02-14

Gear hobbing machine is the most widely used machine tool among gear processing machine tools. Gear hobbing machines can cut spur and helical cylindrical gears, as well as worm gears and sprockets. A gear processing machine that processes spur gears, helical gears and herringbone cylindrical gears and worm gears with hobs according to the processing method. When using special hobs, the machine tool can also process various special tooth-shaped workpieces, such as splines and sprockets. The processing accuracy of ordinary gear hobbing machines is 7 to 6, and the processing accuracy of high-precision gear hobbing machines is 4 to 3.

Design is a critical and initial step in casting. Design is also a critical step in gear casting. It has to do with the quality and level of the cast gear. In the design stage, it is essential to select appropriate casting gear materials, carry out advanced and reasonable structural design, and select reliable gears and bearings.

In the gear processing process, advanced blank forming technology, stable heat treatment process and appropriate surface hardening treatment procedures are all key factors in forming gear quality. For example, there are several key links in the grinding process: by selecting a sharp grinding wheel with low grinding surface stress, the grinding feed can be increased, the grinding time can be shortened, the grinding efficiency can be improved, and the grinding wheel can be dressed. Extend to reduce costs; By using appropriate grinding and grinding wheel parameters, on the premise of ensuring no grinding and ensuring quality, higher grinding parameters should be used as much as possible to shorten grinding time and improve grinding efficiency to Increase output, ensure high precision, and reduce surface roughness; by using appropriate grinding oil, you can ensure good lubrication and rust prevention, which will help reduce surface stress on the grinding tooth surface, avoid damage and cracking, and reduce Roughness. Reduce the degree of clogging of the grinding wheel holes, ensure the sharpness of the grinding wheel, reduce the dressing of the grinding wheel, reduce the number of grinding wheels, and reduce costs.

Previous:

Contact Us

Service Phone:

+86-13630891203, +86-13930960916

E-mail:

554590975@qq.com

Address:

No.16, Xingwan Industrial Zone, Ren County, Xingtai City, Hebei Province