How much do you know about the development and application of high-speed gear hobbing machines?

2021-01-15

With the rapid development of social economy and the continuous advancement of modern society, the mechanization level of all walks of life in society continues to improve. The improvement of mechanization level has improved social productivity and promoted rapid development. As an important basic component in industrial production, gears play an important role in industrial production. At present, the gear industry has developed into a large-scale industry of domestic mechanical basic parts.

Development and application of high-speed gear hobbing machines:

As industrial production puts forward higher requirements for gear accuracy and quality, it also puts forward higher requirements for the processing accuracy of equipment. Accordingly, the development of gear hobbing machines for gear production machinery was driven. Therefore, our country has incorporated the research and development of high-speed gear hobbing machines into the scientific system and has achieved impressive results. The level of manufacturing has been greatly improved. At present, the equipment can be produced independently, and its performance has been greatly improved to better meet the needs of users.

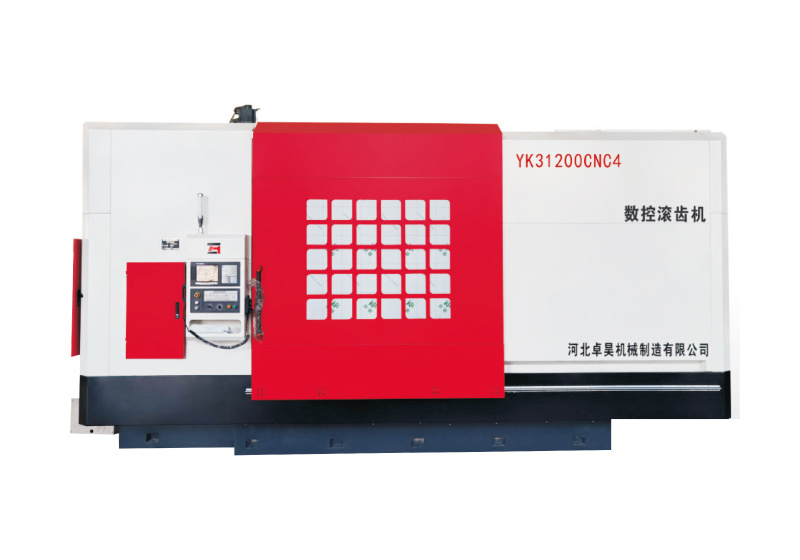

At present, this equipment is suitable for batch, small batch and single-piece production and processing of cylindrical gears, worm gears and drum gears with certain parameters. It can also be used for continuous indexing hobbing of spline hobs with 6 teeth and more than 6 teeth with a length of less than 300. Splined shaft. And the sprocket can be rolled and cut with a sprocket hob. When machining cylindrical gears, up and down milling hobbing can be used, and the entire tooth width can be machined by the axial feed (vertical feed) method. The equipment for hobbing ordinary worm gears adopts the radial feed method. The adjustment and processing methods of the machine when processing spline shafts and sprockets are the same as when processing cylindrical spur gears.

working principle:

When the pump is started, the driving wheel drives the driven gear, which rotates in the opposite direction. The gears mesh well. The teeth of the two gears scrape some of the oil at the inlet, creating a low-pressure suction fluid. The liquid entering the pump body is divided into two paths, pushed forward by the gear in the gap between the gear and the pump casing, and pressed to the oil discharge port to form high pressure and discharge the liquid. The main equipment of the air blowing recovery boiler is: combustion furnace, CNC gear hobbing machine, steam superheater, boiler body, secondary air preheater, soft water heater, air preheater, induced draft fan, and blower.

Contact Us

Service Phone:

+86-13630891203, +86-13930960916

E-mail:

554590975@qq.com

Address:

No.16, Xingwan Industrial Zone, Ren County, Xingtai City, Hebei Province